Steve

`Applying Biomechanics to Achieve

Peak Performance'

AmmSensorTM

A real-time wireless 3D,

Bluetooth enabled, motion sensor

with AmmGraph3DTM display software

for Life Science Applications

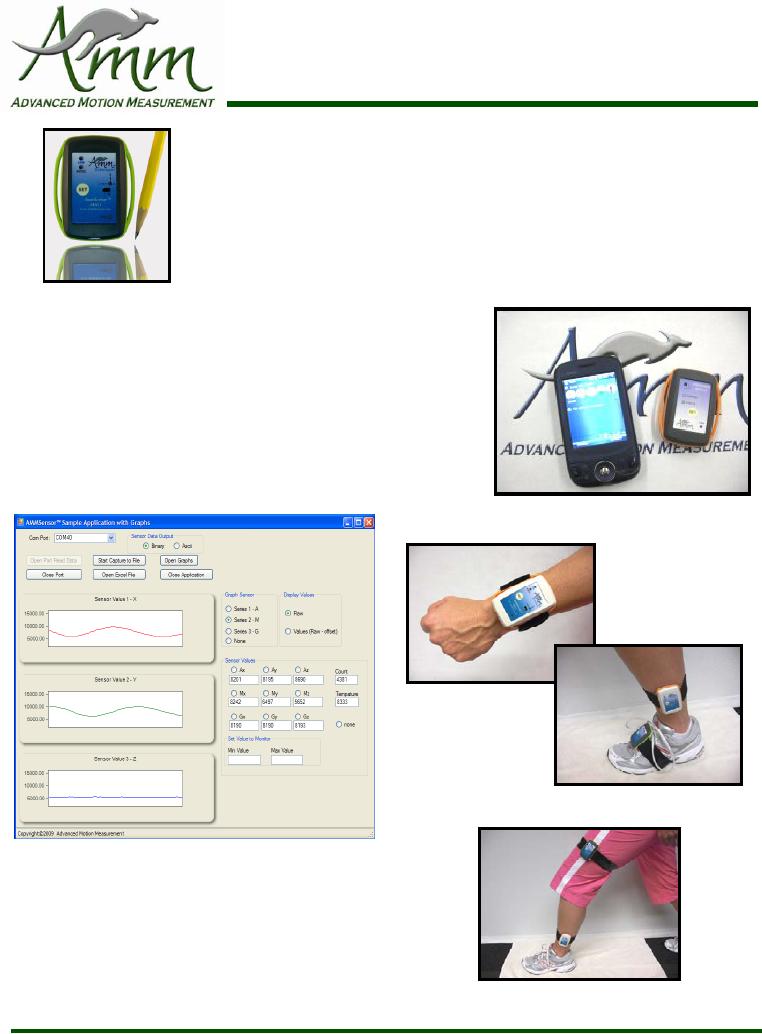

AmmGraph3DTM - is a software package that allows the user to graph all

nine outputs produced and transmitted by the real-time wireless 3D

AmmSensorTM, including X, Y and Z for the accelerometer, magnetometer

and gyro. The nine digital components provided by the (6DOF) inertial

measurement unit (IMU) are: 3D acceleration (Ax, Ay, Az), 3D magnetic field

(Mx, My, Mz), and 3D gyroscope (Gx, Gy, Gz). These data are transmitted

from the AmmSensorTM in real-time to a Windows Mobile 6 hand-held PC or

laptop. AmmGraph3DTM also allows for capture to a comma delimited file,

which opens MS Excel to display the current data.

Once connected the software displays the data values per sensor from all

nine sensor channels in real-time. The main screen is shown below.

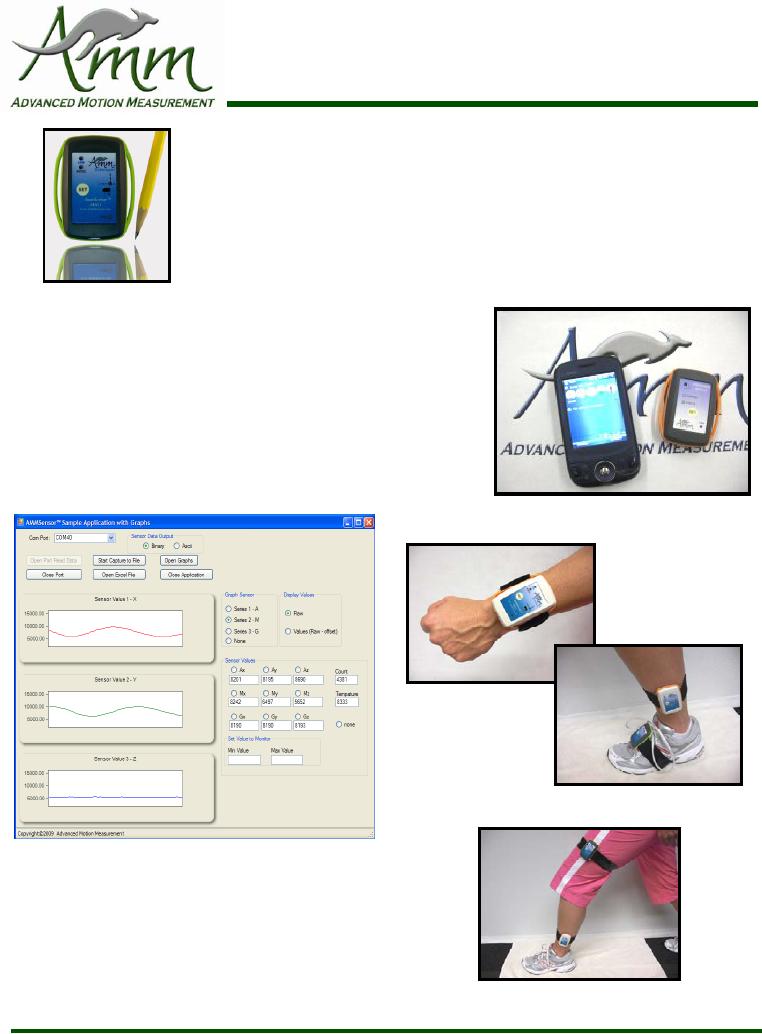

AmmSensor communicates via Bluetooth

directly to a hand-held PC or laptop

Measure and display

e.g. wrist rotation

Place

one AmmSensor

on the tibia and one

AmmSensor on the foot

to measure dorsiflexion

and plantarflexion.

Displaying the AmmGraph3DTMData

After the AmmSensor is turned on, the user chooses the

serial port number and clicks `Open Port' and `Read Data'.

Now real-time data will be streaming on the screen and the

ASCII values will be rapidly changing. The magnetometer,

accelerometer or gyroscope can be chosen to graph by

clicking the appropriate button. The user will see the three

graphs changing when the AmmSensor is moved.

Use AmmSensor for gait applications.

Measure joint angles, e.g. the knee

1202 E. Maryland Avenue, Suite 1J, Phoenix, AZ 85014 USA

Phone: 602-263-8657 Fax: 602-277-2326 email: steve@amm3d.com website: www.amm3d.com

Graphing and Displaying All Channels

To graph all 9 channels of data the user clicks `Start Capture', moves the sensor then clicks `Stop Capture' (the same

button). `Open Graphs' now shows the following screen:

These data are automatically saved to a comma delimited data file which can be read into Excel by clicking the `Open Excel'

button.

AmmSensorTM (AMG1): is a revolutionary new real-time wireless 3D IMU/sensor that is Bluetooth enabled. This 3D

(6DOF) inertial measurement unit (IMU) provides angular data by employing three miniature tri-axial MEMS chips to capture

acceleration, the earth's magnetic vector and angular velocity. AmmSensorTM has 9 digital outputs: acceleration (Ax, Ay,

Az), 3D magnetic field (Mx, My, Mz), and 3D gyroscope (Gx, Gy, Gz). It has a sampling rate of 250Hz and measures

rotational velocity up to a maximum of 2,000 degrees/sec. Bluetooth technology allows the AmmSensorTM to communicate

and transmit 3D motion data to a Windows Mobile 6 compatible cell phone, laptop or any Bluetooth enabled device. Multiple

Bluetooth data links can monitor several sensors at a time, allowing the user to define and use multi-segmental

biomechanical models.

AmmSensorTM is small (2.75" x 1.7" x 0.7" / 68 x 43 x 18), light (1.5 oz/42g) and inexpensive. It is self-contained with an

internal rechargeable battery, which gives it up to eight hours of life. The real-time aspect of the AmmSensorTM allows it to

be used as a biofeedback training tool. Motion biofeedback or motion data logging applications allow AmmSensorTM to be

attached to a segment of the body and communicate directly to a cell phone on your hip, or to a laptop on your desk.

It is the most versatile, low cost; Bluetooth enabled IMU/sensor in the world today! It can measure human motion, machine

motion or any motion! AmmSensorTM has been designed for high speed sports motion (2,000d/s and 12g) but can easily be

switched to measure slower motion for rehabilitation applications (400d/s and -4g). The attractive slim line package can

easily be worn on the wrist, leg, around the waist or on any part of the body!

AmmSensorTM comes with a simple software program that displays and records the nine output values: Ax, Ay, Az, Mx, My,

Mz, and Gx, Gy, Gz. AmmSensor's output can be changed between binary and ASCII by the user. Binary mode provides

250 complete samples per second, whereas ASCII output is 125 samples per second, and is intended for ease-of-use with

any terminal program that can receive 115 KBaud data. These data streams can be mathematically combined to produce

accurate kinematic parameters for pitch, yaw and roll regarding any object to which the sensor is attached. Multiple

A simple software demonstration program in VB will help you write your own programs in most languages: VB, C#, C, Matlab

and Labview. Additional applications are available for motion capture and graphing, plus real-time biofeedback for sports

and rehabilitation training applications.

1202 E. Maryland Avenue, Suite 1J, Phoenix, AZ 85014 USA

Phone: 602-263-8657 Fax: 602-277-2326 email: info@amm3d.com website: www.amm3d.com

For more information call Stephen Cheetham (602) 263-8657

1202 E. Maryland Avenue, Suite 1J, Phoenix, AZ 85014 USA

Phone: 602-263-8657 Fax: 602-277-2326 email: info@amm3d.com website: www.amm3d.com